The Ultimate Guide to Choosing Automatic Carwash Equipment for Your Business

In the competitive world of car wash services, selecting the right Automatic Carwash Equipment is crucial for success. As noted by industry expert John Smith, "The right equipment not only enhances efficiency but also elevates the customer experience." With rapid advancements in technology and increasing customer expectations, business owners must navigate a plethora of options to find equipment that meets their specific needs and operational goals.

Choosing Automatic Carwash Equipment involves understanding various factors such as the scale of your business, the types of services you want to offer, and the target market's preferences. Operating a successful car wash demands not just reliable machinery, but also an investment in quality that can withstand the demands of high turnover while providing an exceptional wash every time. As you embark on this journey, remember that the equipment you choose will play a pivotal role in shaping the customer experience and driving your business's growth.

By prioritizing the right features, technology, and support services available, you can ensure that your Automatic Carwash Equipment not only meets current demands but also has the flexibility to evolve with future trends. This guide aims to assist you in making an informed choice, setting the foundation for a successful and prosperous car wash business.

Key Considerations for Selecting Automatic Carwash Equipment

When selecting automatic carwash equipment for your business, several key considerations must be taken into account. First, evaluate the type of services you want to offer, such as touchless washes or friction washes. According to a recent industry report from IBISWorld, the automatic carwash industry has experienced a growth rate of 4.6% annually over the past five years, reflecting a rising consumer preference for convenience and efficiency. Understanding customer preferences in your area can help you tailor your equipment choices to meet demand.

Another essential consideration is the space available at your location. Space constraints can influence the type and size of the equipment you can install. For instance, inline systems may be ideal for limited spaces, while tunnel systems could optimize throughput in larger facilities. A study by the International Carwash Association indicates that a well-designed layout can enhance workflow efficiency by up to 30%, ultimately leading to increased revenue.

Tips: Always assess the return on investment (ROI) of different equipment options. Consider factors like water usage, energy efficiency, and maintenance costs. The right choice can significantly impact your operating expenses and customer satisfaction. Additionally, explore financing options that allow you to invest in top-of-the-line equipment without straining your budget, enabling you to stay competitive in a growing market.

Analyzing the Different Types of Automatic Carwash Systems Available

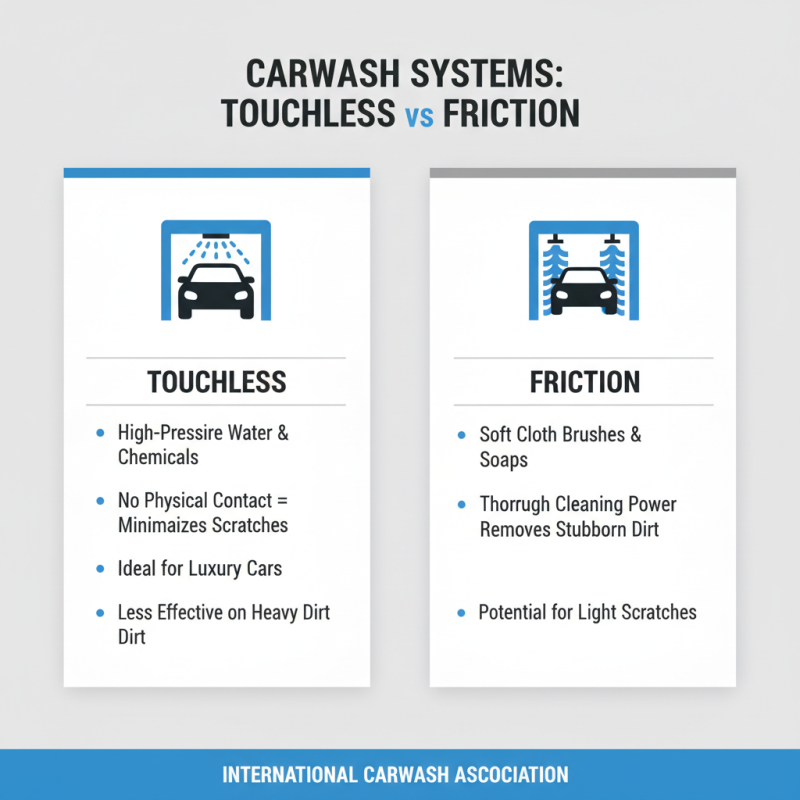

When choosing automatic carwash systems, it is essential to understand the various types available and their suitability for different business models. Two primary categories of automatic carwash systems are touchless and friction systems. According to the International Carwash Association, touchless carwashes utilize high-pressure water jets and specialized chemicals to clean vehicles without physical contact. This method minimizes the risk of scratching the vehicle's surface, making it particularly appealing to customers with higher-end vehicles. However, touchless systems may not achieve the same level of cleaning as friction systems, sometimes leaving behind stubborn dirt and grime.

Friction carwash systems, on the other hand, rely on soft cloths or foam to scrub the vehicle's surface, delivering a thorough clean. Data from the Industry Research Report indicates that friction carwashes have been gaining popularity due to their effectiveness and speed. Many operators find that these systems can increase wash throughput, averaging around 20-25 cars per hour compared to 15-20 for touchless options. However, it is crucial to consider the potential for wear and tear on the vehicle's finish, which may deter some customers. As the carwash industry continues to evolve, understanding these distinctions will help business owners make informed decisions that align with customer preferences and operational efficiency.

Evaluating the Cost of Automatic Carwash Equipment vs. Profit Potential

When considering the installation of automatic carwash equipment, a thorough evaluation of costs versus profit potential is crucial for long-term success. According to the International Carwash Association, the industry has experienced a significant growth rate of approximately 4.4% annually, indicating a robust demand for automated services. The initial investment for automatic carwash systems can range widely, with prices often between $250,000 and $1 million, depending on the complexity and technology used. However, this upfront cost must be weighed against operational efficiencies and increased customer throughput that such equipment can deliver.

The potential return on investment (ROI) for automatic carwash systems can be substantial. Operators report revenue per wash averaging between $15 and $30, which can yield an annual income in the range of $500,000 to over $1 million, depending on location and customer volume. Additionally, since automatic carwashes typically attract more customers due to their convenience and speed, businesses can expect to increase repeat business and customer loyalty. Industry analysts project that with proper location and marketing strategies, automatic carwashes can achieve break-even points within the first 2 to 3 years of operation, making the initial investment a viable option for those looking to enter or expand in the carwash market.

Understanding Industry Standards and Regulations for Carwash Equipment

When selecting automatic carwash equipment for your business, understanding industry standards and regulations is paramount to ensure compliance and safety. Various regulatory bodies have established guidelines that govern the design, operation, and maintenance of carwash facilities. These regulations often include specifications for water usage, chemical disposal, noise levels, and equipment safety features. By adhering to these standards, you can not only ensure the safety of your customers and employees but also contribute to environmental sustainability.

Additionally, staying informed about local and national regulations helps you avoid potential fines and legal issues that may arise from non-compliance. It is essential to conduct thorough research on the applicable laws governing carwash operations in your area. This includes understanding the necessary permits, inspections, and certifications required for your equipment. By prioritizing regulatory compliance from the outset, you position your business for long-term success while fostering a trustworthy reputation in the community.

Maintenance and Support: Ensuring Longevity of Your Carwash Investment

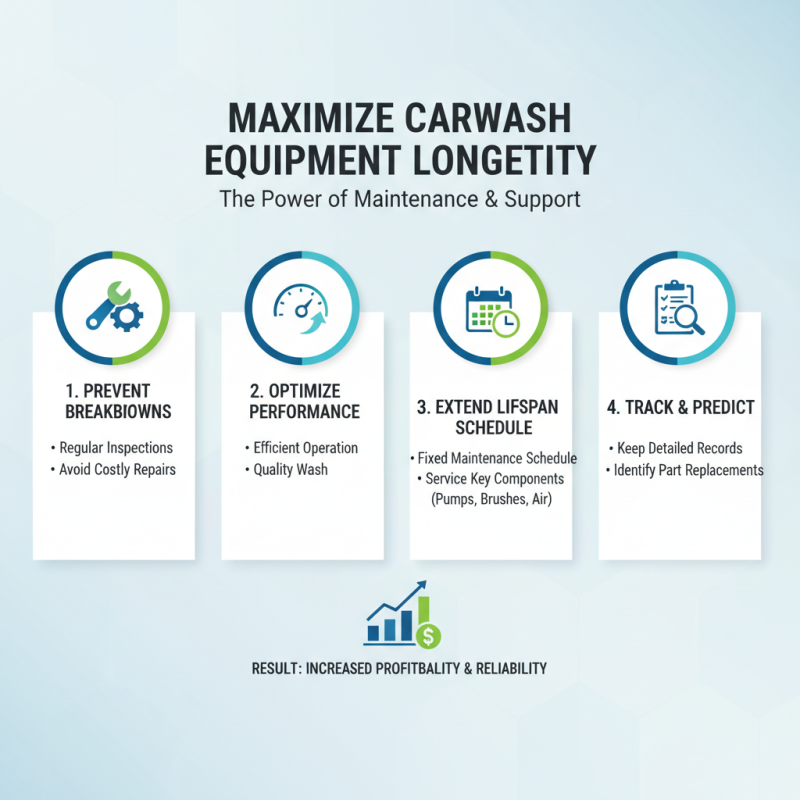

When investing in automatic carwash equipment, maintenance and support play a pivotal role in ensuring the longevity and performance of your carwash business. Regular maintenance not only helps to prevent costly breakdowns but also ensures that the equipment functions efficiently. Establishing a fixed maintenance schedule, including routine inspections and servicing of components such as pumps, brushes, and air systems, can greatly enhance the lifespan of the equipment. Additionally, keeping records of maintenance activities allows for better tracking of performance trends and can indicate when parts may need replacement.

Support is another crucial aspect that cannot be overlooked. Having access to responsive technical support can make all the difference when issues arise, minimizing downtime and protecting your investment. Choosing suppliers that offer robust support services, including troubleshooting assistance and readily available spare parts, can significantly alleviate maintenance concerns. Ensuring your staff is trained in basic upkeep and troubleshooting procedures can also empower them to address minor issues swiftly, promoting a smoother overall operation and a positive customer experience.

Related Posts

-

Revolutionizing Vehicle Care: The Future of Automatic Car Wash Equipment Unveiled

-

Challenges Faced by Buyers When Sourcing Best Self Car Wash Equipment

-

10 Essential Tips for Choosing the Best Fully Automated Car Wash Service

-

The Ultimate Guide to Choosing the Best Drive Through Car Wash Machine for Your Business

-

Revving Up the Future: How Automatic Car Wash Equipment is Transforming Vehicle Care

-

How to Identify Quality Manufacturers for the Best Industrial Car Wash Machine